Share to

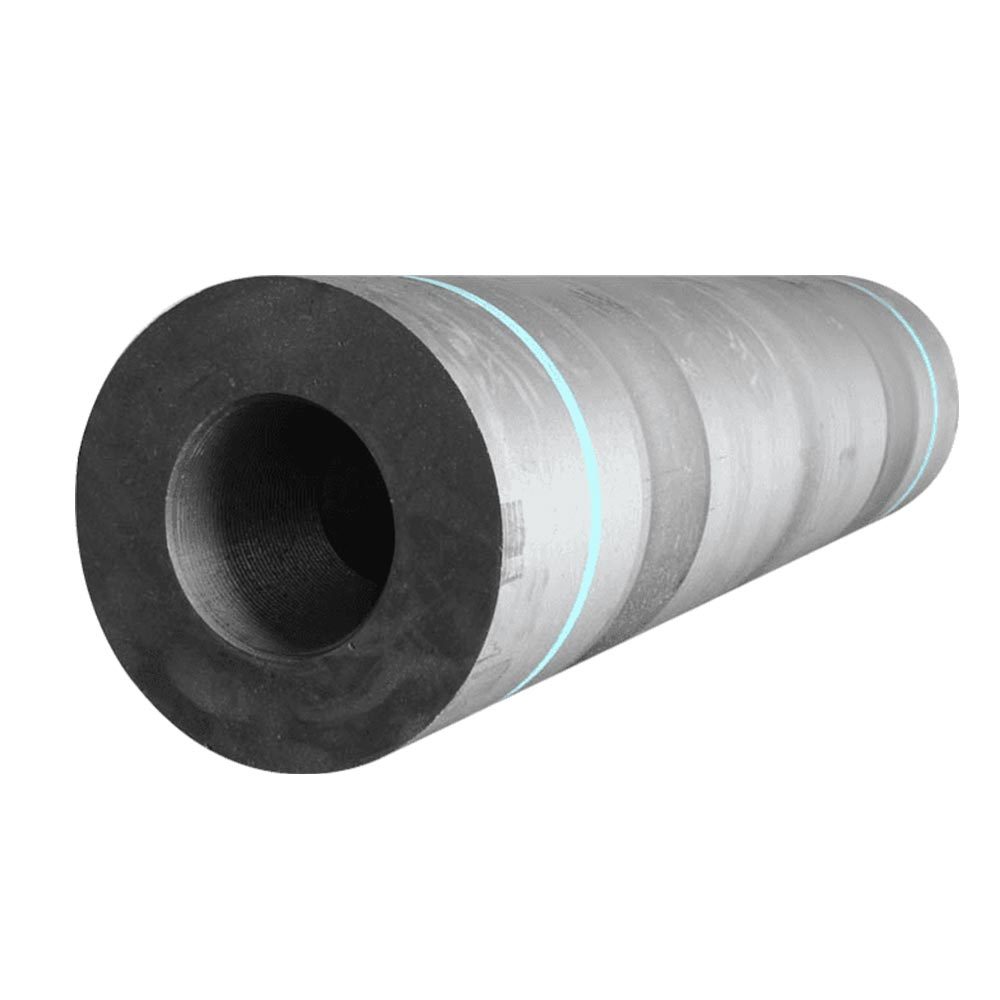

UHP Graphite Electrode

Still deciding? Get samples first, Contact US !

View similar products

Tag list

- Details Information

-

Graphite electrode are the best conductive material for electric arc furnace and smelting furnace,They produced by the high quality needle cokes mixed,molded,baked and graphitization process to form the finished product.Graphite electrode are well suited for use in high-temperature environments and can withstand extreme heat without breaking down.It is presently the only available product that has the high levels of electrical conductivity and the capability of sustaining the extremely high levels of heat generated in the demanding environment.

This feature reduces the energy losses and improves the entire smelting process' efficiency, resulting in less energy consumption and lower production costs.

Graphite Electrode Unique Properties

Graphite electrode is ideal for using in electric arc furnaces and other industrial applications.The unique properties ensure graphite electrode can withstand high temperatures reaching up 3,000°C to and pressures in electric arc furnace(EAF).

High Thermal Conductivity- Graphite electrodes have excellent thermal conductivity, which enables them to withstand high temperatures and pressures during the melting process.

Low Electrical Resistance- The low electrical resistance of graphite electrodes facilitates the easy flow of electrical energy in electric arc furnaces.

High Mechanical Strength- Graphite electrodes are designed to have high mechanical strength to withstand the high temperature and pressure levels in electric arc furnaces.

Excellent Chemical Resistance- Graphite is a highly inert material that is resistant to most chemicals and corrosive substances. Graphite electrodes ideal for use in harsh industrial environments, where other materials may fail due to chemical attack.Graphite electrodes are not only widely used in electric arc furnaces,also used in the production of silicon metal, yellow phosphorus, and other non-ferrous metals,acids, alkalis, and other chemicals, corrosive environments.

Graphite electrodes are classified into three grades based on their physical properties ,specifications and different applications related the electric furnace capacity, transformer power load. The most commonly used grades of graphite electrodes are Ultra-high power (UHP), High power (HP), and Regular power (RP).

UHP Graphite Electrode

Still deciding? Get samples first, Contact US !

Products Category

Keywords

Related Products